The cotter joint is withstanding the load applied during the working condition or not. In this article I am going to present a detailed explanation of the design procedure for Knuckle Joint and Cotter Joint.

Question And Answers Mechanical Engg Diploma Simple Notes Solved Papers And Videos

The material used is carbo n steel fo r.

. 100 but may be as large as 1. TYPES OF COTTER JOINTS 1Socket and spigot cotter joint. Design of rods For the rods under axial load Axial stress in the rods σ 4F πd2 STEP 2.

14 - Mechanical Design - Cotter joint - Read online for free. It is not suitable to connect rotating shafts which transmit torque. Manufacturing method for cotter joint pdf - Manufacturing Method of Cotter Joint1 - Free download as Powerpoint Presentation ppt pptx PDF File pdf Text File txt or view.

Design of Sleeve and Cotter Joint. P So the methodology of the study includes 1. Design of cotter joint.

Q1 Design a cotter joint to connect two mild steel rods for a pull of 30 kN. The sleeve and cotter joint is shown in Fig. Elemental analysis at various loads.

Design an d draw a cotter joint to support a load varying from 30 N in compression to 30 KN in tension. Design of the spigot and the Cotter a Crushing strength of the cotter Fd1tσc b Axial stress across the slot of the rod σ 4F πd1 24d 1t STEP 3. Cotter joint uses one or two cotters to connect two rods rigidly transmitting forces and motion with no rotation of the rods 3.

Two rods connected by means of cotter joint Inside diameter of the socket joint and outer diameter of the socket collar are 50 and 100 mm respectively. Types of gear pdf gib and cotter joint socket and spigot joint classification of brakes types of fire in hindi application of cotter joint different types of brakes and their applications type of fire in hindi arduino projects ideas mechanical drill knuckle joint application application of knuckle joint type of gear difference between cotter joint and knuckle joint socket and. The cotter passes through slots made in two coaxial parts and thus prevent the relative motion between them.

DESIGN PROCEDURE FOR COTTER JOINT The basic procedure to calculate the dimensions of the cotter joint consists of the following steps. Sleeve and Cotter Joint. 3Gib and cotter joints.

WHAT IS A COTTER JOINTS A cotter is a flag wedge shaped piece of steel. The maximum permissible stresses are 55 MPa in tension. COTTER JOINT A cotter joint is used to connect rigidly two co-axial rods or bars which are subjected to axial tensile or compressive forces.

Types of Cotter JointThere are three types1 socket and Spigot Cotter Joint2 Sleeve Cotter Joint3 Gib. Keys Cotter and 55 COTTER AND COTTER JOINT Knuckle Joints A cotter is a metallic strip of uniform thickness but tapers in width. It is a temporary fastening.

A Knuckle Joint is used for the application of the Tie rod joint of jib crane or Tension link in the structure of the bridge. 40 MPa in shear and 70 MPa in crushing. T031 d Calculate the diameter d 2 of the spigot on the basis of tensile stress.

Design of Sleeve and Cotter Joint. NUMERICALS ON THE DESIGN OF COTTER JOINT. Design of Cotter Joint - Free download as Powerpoint Presentation ppt PDF File pdf Text File txt or view presentation slides online.

CAD Model of cotter joint assembly. Gib and Cotter Joint. The cotter in the cotter joints fails due to double shear.

Calculate the diameter of each rod by Calculate the thickness of the cotter by the t empirical relationship given in Eq. Cotter and Knuckle Joints431469. The rods subjected to tensile force of 50kN.

Design of Gib and Cotter Joint for Strap End of a Connecting Rod. Design of cotter jointA cotter is a rectangular element. Meshing of cotter joint using ANSYS R15.

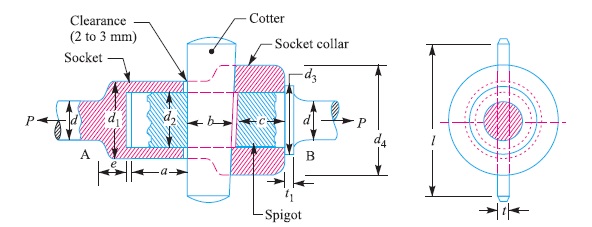

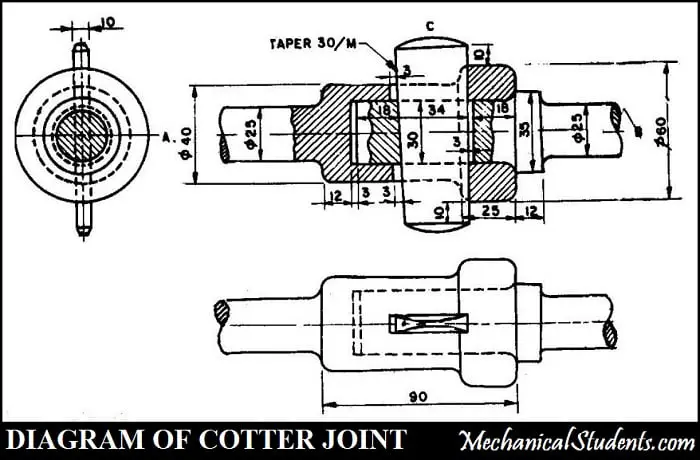

One of the rods is formed into a socket by enlarging its end while the other rod called spigot end is formed with enlarged diameter and an integral collar The spigot is put inside the socket and the cotter is driven through the slots in socket and spigot ends. Joint between the piston rod and the crosshead of a steam engine. Types of Cotter Joints.

Socket and spigot cotter joint is used to connect circular rods. CAD Model of cotter joint using CATIAV5R20. Design of cotter joint.

2Sleeve and cotter joints. A cotter joint is used to connect the two shafts which are either subjected to tensile or compressive axial force. A cotter is a flat wedge shaped piece of rectangular cross section and its width is tapered either on one side or on both sides from one end to another.

The cotter made of steel 30C8 S yt 400 Nmm 2 and the factor of safety fos4. Download Manufacturing Method Of Cotter Joint - Copy. The taper may be very small like 1.

Axes of the rods to be joined should be collinear. It is not used to connect the shafts that are rotating or transmitting torque. Socket and Spigot Cotter Joint.

Design of Socket and Spigot Cotter Joint. Draw a neat sketch of the joint designed. Design of the cotter.

Let P Load carried by the rods d Diameter of the rods d1 Outside diameter of sleeve d2 Diameter of the enlarged end of rod t Thickness of cotter l Length of cotter b Width of cotter a Distance of the rod end from the beginning to the cotter hole. Q2 Design a knuckle joint to connect two mild steel bars under a tensile load of 25 kN. DESIGN OF COTTER JOINT 91 Introduction Cotter joint is used to connect two rods subjected to axial tensile or compressive loads.

Cotter Joint for Circular rods Socket and spigot.

Socket And Spigot Cotter Joint And It S Design Engineers Gallery

Design Of Socket And Spigot Cotter Joint Pdf Bending Strength Of Materials

Design Of Cotter Joint Pdf Cotter Joint A Cotter Joint Is Used To Connect Rigidly Two Co Axial Rods Or Bars Which Are Subjected To Axial Tensile Or Course Hero

Question And Answers Mechanical Engg Diploma Simple Notes Solved Papers And Videos

Machine Design Lesson 9 Design Of Cotter Joint

Pdf Machine Design Design Of Riverted Cotter Knuckle Joints

Design Procedure Of Cotter Joint Socket And Spigot Joint Design Of Machine Youtube

Design Procedure For Knuckle Joint Cotter Joint Formulas Pdf

0 comments

Post a Comment